The Gekay Difference

Our customers count on us to help manage equipment and equipment costs. Whether implementing new technology or creating Customized Service Programs we take the extra steps in an effort to exceed customer expectations.

Gekay's commitment to Superior Service is backed by years of vending experience combined with new and innovative processes that have helped to create The Gekay Difference.

We invite you to experience The Gekay Difference by learning more about our unique repair and remanufacturing process.

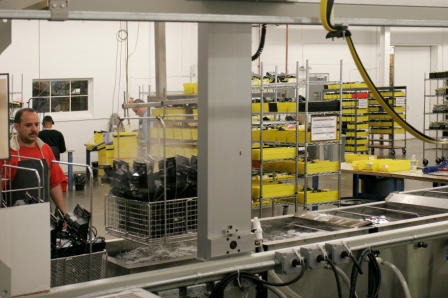

Ultrasonic Cleaner

Gekay has taken remanufacturing to new levels by incorporating Ultrasonics into our cleaning process. Our state of the art Ultrasonic Cleaner removes corrosion and grime from even the hardest to get areas of Payment Systems and Fountain Equipment. All traces of dirt and salt build-up are completely removed.

Bead Blaster

Our Bead Blaster uses thousands of tiny glass particles to remove the worst possible grime off components. We are able to salvage parts and make them 100% functional.

This technology allows us to keep your average repair cost low and to extend useful life of equipment.

Before

After

Quality Control

Quality is a top priority at Gekay. Our ability to deliver a high quality product at a competitive price allows our customers to better manage equipment costs, to increase revenue and to better serve their customer base. We take the extra steps to insure we meet or exceed our customer's expectations.

We have a dedicated Quality Control Department that tests all repaired and remanufactured units before leaving the building. Standards have been developed to insure consistency among the various Quality Control Technicians.

As part of the QC process, each repaired payment system is "burned-in" for a minimum of eight hours. The burn-in process helps identify those units that have intermittent issues. Most often the only way to identify these issues is by simulating field conditions.

Unit History Reports

Our technicians receive a complete history report for each unit that has been repaired by Gekay in the past. This historical data allows the technicians to diagnose and repair root causes rather than performing short term solutions focused on symptoms.

Reporting & Customer Review

Customers can save money....... Every returned unit is tagged with a Warranty Report Form or Customer Request Form. These documents allow Gekay to report our findings back to customers to track repair or user issues such as incorrect switch settings, wrong harnessing, etc.

Our Quality Control initiatives are constantly reviewed and improved upon. Our goal is to provide a level of service combined with timely information that allow our customers to be more efficient and profitable.

Custom Service Center Software

We have developed and utilize a Custom Service Center Software Program. All units are entered into our system to provide complete accountability and historical data. Key customer benefits include:

Itemized invoices

Provides line item detail of every repaired unit, to include all

labor and parts. Our invoicing is transparent, easy to understand, and contains no hidden costs.

Ability to manage multiple customer preferences

Enables customers to provide Gekay

with repair specifications so that we fix ONLY what you want us to fix. Customers can set repair

dollar limits to help better manage repair costs.

Historical data reporting

Gekay can provide specific repair data on all equipment to

aid in the management of equipment, operational issues, and overall costs.

Warranty management

As a Factory Authorized Service Center, we do not charge for repairs

that are within the manufacturer's warranty. We help customers understand how to determine if a unit

is in warranty so they can better control and understand costs. We also offer various repair warranty

programs that are backed up by our quality standards.

Electronic Invoicing

All invoicing is available electronically.

Factory Authorized Service Center

An Authorized Service Center (ASC) has been authorized by a Manufacturer to perform repairs on their behalf. The major advantages of using an Authorized Service Center are:

Units that are within the manufacturers warranty are repaired at no charge.

The ASC has access to all the latest software and updates so that repaired units are equipped with the latest revisions.

The ASC has access to all diagnostic software that is required to properly repair and calibrate equipment and its' components.

The ASC has access to all parts necessary to repair your equipment so that it meets all of the manufacturer's specifications. This insures that the integrity of the warranty is never compromised.

Experience

Gekay prides itself on retaining quality people. Over the years we have established a solid core group of employees. Years of service for the managerial staff ranges from 10 to 35 years. Most of our Technical Supervisors have been with the company for at least ten years. Many technicians have over 10 years of Gekay experience. Many Associates have experience working in the field with customers. They know exactly how our service impacts our customer's operations.

We constantly add to our core group of dedicated employees. It is these people who insure that we provide a consistent and stable service that our customers expect and rely upon.

Facility

Our 65,000 square foot facility provides the space to operate most efficiently. We have multiple expansion possibilities as we continue to grow our current service and as we add new lines.