Services We Provide

Coin Mechanism, Bill Acceptor and Control Board Repair

Gekay is the leading Repair Service for Payment Systems and Control Boards in the Vending and Amusement Industries.

Our customer base includes:

- Beverage Bottlers

- Full Line Vending & Amusement Operators

- The United States Military

- Equipment Manufacturers

- Laundromats

- Car Washes

- Transit Authorities

Products We Repair

Bill Acceptors

| MEI | VN2500 Series | VN2300 Series | AE2400 Series | AE2600 Series | AE2800 Series |

| SC6600 Series | RS3900 Series | LE3800 Series | LRC Cassettes | VFM3 | |

| VFM1 | L005 | Talos | |||

| Conlux | NBM-300 Series |

Coin Mechanisms

| MEI | CF7312 | CF7512 | VN4000 | VN4010XV | VN4510 |

| All TRC Series | All MC Series | Gryphon | |||

| Conlux | CCM5G | USL Series |

Control Boards

| Automatic Products | 110 Series | 120 Series | 4000-5000 | 6000-7000 | LCM4 |

| Robo Quencher | |||||

| Dixie Narco | "P" Series | MPC | S2 | S2D | S3D |

| DN5000 main control board | DN5000 KO board | DN5000 display board | Dixie Narco Bottle Drop - MDB | ECC Bottle Drop - MDB | |

| ECC Bottle Drop - Micro Mech | |||||

| Royal | G2 | Newer G3 | Older G3 | Merlin 2 | Merlin 3 |

| Merlin 4 | |||||

| FastCorp | 820 main control board | 631 main control board | Triac Power Supply | ||

| Rowe | BC-10 | BC-11 | BC-22 | BC-25 | BC-1000 |

| BC-1200 | BC-1400 | BC-3500 | |||

| Vendo | VEC 12.3 | VEC 12.2 | VEC 12.1 | VEC 9.3 | VEC 9.2 |

| VEC 9.1 | VEC 5.2 | VEC 5.1 | VEC 5.0 |

Card Readers

| Debitek | DB-8000 | DB-8002 |

Locks

| Triteq | All Locks |

Fountain Equipment Remanufacturing

Our Fountain Remanufacturing Department is currently focused in three main areas:

- Bar Guns

- Carbonators

- Cold Plates

We provide a quick turnaround on equipment and return product in "like new" condition. Please check back with us as we will be adding new Fountain products to our remanufacturing service.

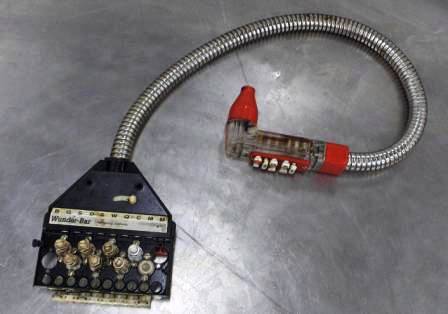

Bar Guns

Bar Gun Remanufacturing

- "Like new" field ready product

- All handle o-rings, flavor button, and defective parts replaced

Repair Process

- Evaluation

- Pre-Wash

- First sanitization

- Complete disassembly

- Cleaned via Ultrasonic Cleaner

- Clean internals

- Reassemble

- Second sanitization

Quality Control

- Liquid pressure tested at 120lbs

- Soda flow rates set at 6.5 oz. in 5 seconds

- Leak tested

- Boxed and labeled with bar gun configuration

Custom Remanufacturing Programs

- Available upon request

Before

After

Carbonators

Evaluation Process

- Remove all old fittings

- Cap and Pre-wash

- Inspect power cord for damage

- Pressure test Brass Pump outlet PSI is at 250lbs

- Ensure relief valve releases at 180lbs

- Confirm backflow preventor and check valves are not leaking

- Ensure tank and motor mounts are secure

Cleaning

- Cap all outlets

- Spray on environmentally safe detergent

- Cycle through the Ultrasonic Cleaning System

- Remove Brass Pump, seal and bead blast

Operational Testing

- Oil motor ports with 20W electric motor oil

- Flood tank, set CO2 pressure at 110lbs and cycle 4 times

- Blowout tank with CO2 and seal outlets

Before

After

Cold Plates

Cold Plate Remanufacturing Standard Procedure

- Pressure test for leaks

- Flush any syrup remaining in the circuits

- Clean units using our Aqueous Ultra Sonic Cleaning System (140 degree water temperature)

- Disinfect using Farm & Food industry disinfectant

- Sanitize units using Kay-5 sanitizer

- Flush all circuits to remove water, disinfectant and sanitizer

- Dry, cap and pack units for delivery

Before

After